Product Description

|

Chemical composition |

||||||

|

Material |

C |

Si |

Mn |

P |

S |

Cr |

|

52100 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

0-0.571 |

0-0.571 |

1.40-1.65 |

FAQ

1. Can you provide sample free?

We’re pleased to offer you free samples weighing up to 0.5kg. It’s our way of letting you experience the quality of our products firsthand. If there’s a specific product you’d like to try, simply let us know, and we’ll ensure it reaches you promptly.

2. What kind of payment terms you can accept?

We can accept T/T,L/C, Western Union and Paypal.

3. What about your steel ball’s quality?

We pride ourselves on the exceptional quality of our steel balls. Our commitment to delivering top-tier products is evident throughout the entire manufacturing process. Every steel ball undergoes rigorous scrutiny, with a comprehensive 100% inspection conducted before shipment. Rest assured, our dedication to quality assurance ensures that you receive products of the highest standard.

4. What’s your packing method?

A) Inner packing: Dry packing or oil packing are provided according to you needs.

B) Outer packing:

1)volatile rust preventive paper + poly bag + iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

3)customized packing.

5. What’s your delivery time?

Within 3-30 days according to your required size and quantity.

6. Is your steel ball competitive?

Yes, We are steel ball manufacture more than 30+ years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, IATF 16949 |

| Standard Parts: | Yes |

| Samples: |

US$ 20/kg

1 kg(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

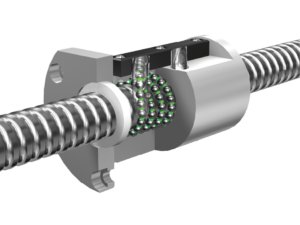

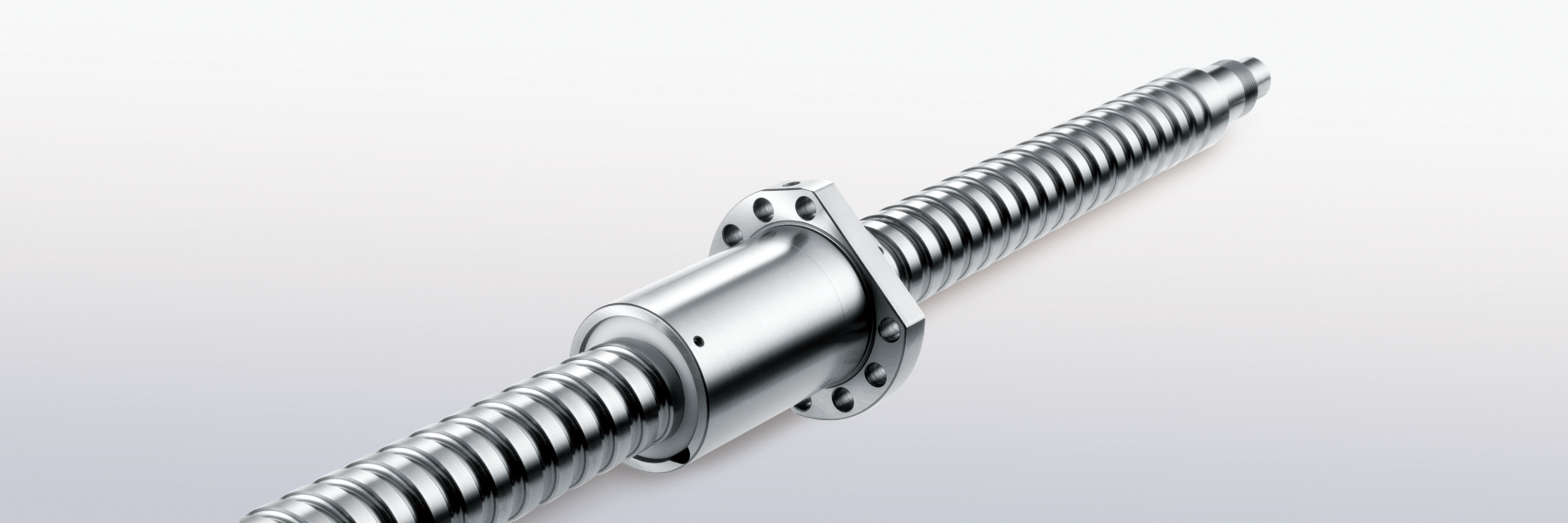

What are the latest innovations in screw ball technology?

In recent years, there have been several notable innovations in screw ball technology aimed at improving performance, efficiency, and reliability. These advancements have been driven by the demand for higher precision, increased speed, reduced friction, and improved longevity in various industries that rely on linear motion systems. Here are some of the latest innovations in screw ball technology:

- High-Speed and High-Accuracy Designs: Manufacturers have developed screw ball designs that can operate at higher speeds while maintaining high levels of accuracy. These designs often incorporate optimized geometries, advanced materials, and improved manufacturing techniques to minimize vibration, reduce noise, and enhance dynamic response. High-speed and high-accuracy screw balls enable faster and more precise positioning in applications such as robotics, CNC machines, and automation systems.

- Advanced Materials and Coatings: The use of advanced materials and coatings has significantly contributed to the performance and longevity of screw balls. For example, the adoption of high-performance steels, ceramics, or composites for critical components such as ball bearings and raceways can enhance load-carrying capacity, reduce friction, and increase resistance to wear and corrosion. Additionally, specialized coatings like DLC (Diamond-Like Carbon) or ceramic coatings can provide improved lubricity, surface hardness, and resistance to contaminants.

- Integrated Sensors and Monitoring Systems: Innovations in screw ball technology have led to the integration of sensors and monitoring systems directly into the assembly. These sensors can measure parameters such as temperature, vibration, load, and position, enabling real-time monitoring of the screw ball’s performance and condition. This data can be used for predictive maintenance, early fault detection, and optimizing the operation of the linear motion system.

- Lubrication and Sealing Technologies: Improved lubrication and sealing technologies have emerged to enhance the performance and longevity of screw balls. Lubricants with advanced formulations and additives can offer better viscosity-temperature characteristics, extended lubrication intervals, and improved resistance to oxidation and contamination. Sealing technologies have also evolved to provide better protection against dust, moisture, and other environmental factors, reducing the risk of premature wear and damage.

- Efficiency and Energy-Saving Features: Innovations in screw ball technology have focused on optimizing efficiency and reducing energy consumption. For instance, designs incorporating recirculation systems with reduced friction and improved ball return mechanisms can minimize power losses and increase overall system efficiency. Energy-saving features such as low-friction ball nuts, optimized ball-to-raceway contact, and improved lubrication systems contribute to reduced power requirements and improved energy efficiency.

- Smart and Networked Capabilities: Screw ball technology has embraced the trend of connectivity and smart functionality. Some advanced screw ball systems now offer networked capabilities, allowing integration with industrial automation systems, IoT platforms, and data analytics tools. This enables remote monitoring, diagnostics, and data-driven optimization of the linear motion system, leading to improved productivity, predictive maintenance, and enhanced performance.

These are just a few examples of the latest innovations in screw ball technology. It is worth noting that ongoing research and development continue to push the boundaries of what is possible, introducing new materials, designs, and features to meet evolving industry demands. By leveraging these innovations, industries can benefit from improved precision, speed, reliability, and efficiency in their linear motion applications.

How do temperature variations affect the performance of screw balls?

Temperature variations can have a significant impact on the performance of screw balls, also known as ball screws. These linear motion systems are designed to operate within specific temperature ranges to maintain their accuracy, dimensional stability, and overall performance. Here’s how temperature variations can affect the performance of screw balls:

- Thermal Expansion: Screw balls are typically composed of different materials, such as steel or ceramics, that have different coefficients of thermal expansion. When the temperature changes, each material expands or contracts at a different rate, leading to dimensional changes in the screw ball components. This thermal expansion can introduce misalignment, increased backlash, or changes in preload, affecting the accuracy and repeatability of the linear motion system.

- Lubrication: Temperature variations can impact the properties and performance of the lubricant used in screw balls. Lubricants have specific viscosity and temperature ranges in which they function optimally. High temperatures can cause lubricants to thin out, reducing their ability to provide sufficient lubrication and increasing friction between the ball bearings and the raceway. On the other hand, low temperatures can cause lubricants to thicken, impeding smooth motion and increasing resistance. Insufficient or improper lubrication due to temperature variations can lead to increased wear, reduced efficiency, and potential premature failure of the screw ball system.

- Material Integrity: Extreme temperature variations can affect the mechanical properties and integrity of the materials used in screw balls. High temperatures can cause thermal degradation, softening, or even melting of certain materials, leading to reduced strength, increased wear, and potential deformation. Conversely, low temperatures can make materials brittle and more susceptible to fracture or failure under load. It is important to consider the temperature limits of the screw ball materials to ensure their structural integrity and long-term performance.

- System Rigidity: Temperature changes can affect the rigidity and stiffness of the screw ball assembly. When subjected to high temperatures, the components may expand, leading to a decrease in overall system rigidity. This reduction in stiffness can result in increased deflection, reduced accuracy, and diminished load-carrying capacity. Conversely, low temperatures can cause contraction and increased system rigidity, potentially affecting the smoothness of motion and overall performance.

- Sealing and Environmental Protection: Temperature variations can impact the effectiveness of seals and environmental protection measures in screw ball assemblies. Seals play a crucial role in preventing contaminants, moisture, and debris from entering the system. Extreme temperature changes can cause seals to degrade, lose flexibility, or become brittle, compromising their sealing properties. This can result in increased risk of contamination, accelerated wear, and reduced performance of the screw ball assembly.

To mitigate the effects of temperature variations on screw ball performance, several measures can be taken. These include:

- Choosing materials with suitable temperature resistance and low coefficients of thermal expansion.

- Using lubricants that are specifically formulated for the expected temperature range.

- Implementing temperature compensation techniques to maintain dimensional accuracy and alignment.

- Applying thermal barriers or insulation to minimize the transfer of heat to the screw ball assembly.

- Ensuring proper sealing and protection from extreme temperature environments.

- Using temperature control systems or environmental enclosures to maintain a stable operating temperature.

By considering the potential effects of temperature variations and implementing appropriate measures, the performance and longevity of screw balls can be optimized, ensuring accurate and reliable linear motion in various applications.

What is a screw ball and where is it commonly used?

A screw ball, also known as a knuckleball, is a type of pitch in baseball that is characterized by its erratic and unpredictable movement. Unlike most pitches that follow a predictable trajectory, the screwball moves in an unconventional manner, often resembling a combination of a fastball and a curveball. It is thrown by applying a specific grip and using a throwing motion that imparts spin and a unique arm angle.

The screwball gets its name from the way it breaks or “screws” away from a pitcher’s arm side. For a right-handed pitcher, the ball typically moves from right to left (away from right-handed hitters) and vice versa for a left-handed pitcher. This movement is opposite to that of a regular curveball, which breaks towards the pitcher’s arm side.

Due to its unusual and deceptive movement, the screwball can be challenging for batters to track and hit accurately. It can break late and sharply, making it difficult to anticipate its path. The unpredictability of the screwball makes it an effective weapon for pitchers to keep hitters off balance and induce swings and misses or weak contact.

While the screwball was more commonly used in the early decades of baseball, it has become a relatively rare pitch in modern professional baseball. The pitch requires a specific throwing motion and grip that can put strain on a pitcher’s arm and increase the risk of injury. As a result, many coaches and organizations discourage or outright prohibit young pitchers from learning or throwing the screwball to protect their long-term arm health.

It’s worth noting that the screwball is still seen occasionally in professional baseball, typically from pitchers who have mastered the mechanics and have the necessary arm strength and flexibility to throw the pitch safely. However, its usage is far less prevalent compared to other pitches like fastballs, curveballs, sliders, or changeups.

In summary, a screwball is a pitch in baseball known for its erratic and unpredictable movement. While it was once more commonly used, it has become less prevalent due to concerns about arm health. When thrown correctly, the screwball can be a challenging pitch for batters to hit, offering a unique strategic advantage to pitchers who can effectively utilize it.

editor by CX 2024-03-06