Product Description

|

Chemical composition |

|

|

|

|

|

|

||||||

|

Material |

C |

Si |

Mn |

P |

S |

Cr |

||||||

|

52100 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

0-0.571 |

0-0.571 |

1.40-1.65 |

||||||

1.Can you provide sample free?

Yes ,we can provide free samples with in 0.5kg.

2.What kind of payment terms you can accept?

We can accept T/T,L/C, Western Union and Paypal.

3.What about your steel ball’s quality?

Checking in the whole manufacturing process &100% inspection before shipment ensure the quality of our products.

4.What’s your packing method?

A) Inner packing: Dry packing or oil packing are provided according to you needs.

B) Outer packing:

1)volatile rust preventive paper + poly bag + iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

3)customized packing.

5.What’s your delivery time?

Within 3-30 days according to your required size and quantity.

6.Is your steel ball competitive?

Yes, We are steel ball manufacture more than 30+ years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Non-Customized |

|---|---|

| Certification: | ISO, IATF16949 |

| Standard Parts: | Yes |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample steel ball

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

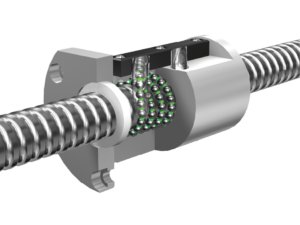

What are the latest innovations in screw ball technology?

In recent years, there have been several notable innovations in screw ball technology aimed at improving performance, efficiency, and reliability. These advancements have been driven by the demand for higher precision, increased speed, reduced friction, and improved longevity in various industries that rely on linear motion systems. Here are some of the latest innovations in screw ball technology:

- High-Speed and High-Accuracy Designs: Manufacturers have developed screw ball designs that can operate at higher speeds while maintaining high levels of accuracy. These designs often incorporate optimized geometries, advanced materials, and improved manufacturing techniques to minimize vibration, reduce noise, and enhance dynamic response. High-speed and high-accuracy screw balls enable faster and more precise positioning in applications such as robotics, CNC machines, and automation systems.

- Advanced Materials and Coatings: The use of advanced materials and coatings has significantly contributed to the performance and longevity of screw balls. For example, the adoption of high-performance steels, ceramics, or composites for critical components such as ball bearings and raceways can enhance load-carrying capacity, reduce friction, and increase resistance to wear and corrosion. Additionally, specialized coatings like DLC (Diamond-Like Carbon) or ceramic coatings can provide improved lubricity, surface hardness, and resistance to contaminants.

- Integrated Sensors and Monitoring Systems: Innovations in screw ball technology have led to the integration of sensors and monitoring systems directly into the assembly. These sensors can measure parameters such as temperature, vibration, load, and position, enabling real-time monitoring of the screw ball’s performance and condition. This data can be used for predictive maintenance, early fault detection, and optimizing the operation of the linear motion system.

- Lubrication and Sealing Technologies: Improved lubrication and sealing technologies have emerged to enhance the performance and longevity of screw balls. Lubricants with advanced formulations and additives can offer better viscosity-temperature characteristics, extended lubrication intervals, and improved resistance to oxidation and contamination. Sealing technologies have also evolved to provide better protection against dust, moisture, and other environmental factors, reducing the risk of premature wear and damage.

- Efficiency and Energy-Saving Features: Innovations in screw ball technology have focused on optimizing efficiency and reducing energy consumption. For instance, designs incorporating recirculation systems with reduced friction and improved ball return mechanisms can minimize power losses and increase overall system efficiency. Energy-saving features such as low-friction ball nuts, optimized ball-to-raceway contact, and improved lubrication systems contribute to reduced power requirements and improved energy efficiency.

- Smart and Networked Capabilities: Screw ball technology has embraced the trend of connectivity and smart functionality. Some advanced screw ball systems now offer networked capabilities, allowing integration with industrial automation systems, IoT platforms, and data analytics tools. This enables remote monitoring, diagnostics, and data-driven optimization of the linear motion system, leading to improved productivity, predictive maintenance, and enhanced performance.

These are just a few examples of the latest innovations in screw ball technology. It is worth noting that ongoing research and development continue to push the boundaries of what is possible, introducing new materials, designs, and features to meet evolving industry demands. By leveraging these innovations, industries can benefit from improved precision, speed, reliability, and efficiency in their linear motion applications.

What are the signs of wear and tear in screw balls?

Over time, screw balls, also known as ball screws, can experience wear and tear due to various factors such as usage, load, environmental conditions, and maintenance practices. It is important to monitor the condition of screw balls regularly to detect signs of wear and tear, as this can affect their performance and reliability. Here are some common signs of wear and tear in screw balls:

- Increased Backlash: Backlash refers to the amount of free motion or play between the screw and the nut. Excessive wear can lead to increased backlash, causing a noticeable looseness or play in the linear motion system. If you observe a significant increase in backlash, it may indicate wear in the ball bearings, raceway, or ball nut, and it could affect the precision and repeatability of the system.

- Irregular or Uneven Motion: As screw balls wear, they may exhibit irregular or uneven motion during operation. This can manifest as jerky or inconsistent movement, vibration, or a non-smooth linear motion. It may be an indication of worn or damaged ball bearings, raceway, or misalignment, resulting in compromised performance and accuracy.

- Unusual Noise: A change in the noise emitted during operation can be an indication of wear and tear in screw balls. Excessive wear can produce grinding, scraping, or unusual noise patterns, which may suggest contact between worn components, lack of lubrication, or damaged ball bearings. Unusual noise should be investigated promptly to identify and address the underlying cause.

- Reduced Overall Performance: Wear and tear in screw balls can lead to a decline in overall performance. You may notice a decrease in positioning accuracy, repeatability, or load-carrying capacity compared to the system’s original specifications. If the screw ball assembly is not performing as expected or is unable to meet the application requirements, it could be a sign of wear and degradation.

- Increased Friction: Worn screw balls may exhibit increased friction during operation. This can result in higher torque requirements, reduced efficiency, and increased power consumption. If you observe a noticeable increase in resistance or difficulty in moving the assembly, it could indicate wear in the ball bearings, raceway, or inadequate lubrication.

- Visible Damage or Deformation: Visual inspection of the screw ball components can reveal signs of wear and tear. Look for visible damage, deformation, or signs of pitting, scoring, or corrosion on the ball bearings, raceway, or ball nut. Any signs of physical damage should be investigated further to determine the cause and assess the extent of wear.

- Reduced Lifespan: If a screw ball assembly has been in use for an extended period and is experiencing more frequent failures or requires frequent repairs, it may indicate accelerated wear and a reduced overall lifespan. Premature failure or decreased reliability can be an indication of significant wear and tear in the system.

Regular inspection, maintenance, and timely replacement of worn components are essential to ensure optimal performance and longevity of screw balls. If you observe any of the signs mentioned above or suspect wear and tear in your screw ball assembly, it is advisable to consult the manufacturer’s guidelines, seek professional assistance, or replace the worn components to restore the performance and reliability of the system.

What materials are screw balls typically made from?

Screw balls, or ball screws, are typically made from a combination of materials carefully chosen to provide durability, strength, and smooth operation. The specific materials used can vary depending on the application requirements and environmental conditions. Here are some commonly used materials for screw balls:

- Steel: Steel is one of the most common materials used for screw balls due to its excellent strength and durability. Typically, hardened alloy steel, such as chrome steel or stainless steel, is utilized to withstand high loads, resist wear, and maintain dimensional stability. Steel screw balls are suitable for a wide range of applications, including industrial machinery, automotive systems, and aerospace equipment.

- Ceramic: In certain specialized applications, ceramic screw balls may be used. Ceramic materials, such as silicon nitride (Si3N4) or zirconia, offer advantages such as high hardness, superior corrosion resistance, and reduced friction. Ceramic screw balls are commonly employed in high-speed or high-temperature environments, where their exceptional properties contribute to improved performance and longevity.

- Plastic: For specific applications where lightweight components or electrical insulation are required, plastic screw balls can be utilized. Materials like nylon, polyoxymethylene (POM), or polyether ether ketone (PEEK) are commonly used for plastic screw balls. These materials offer reduced weight, low friction, and corrosion resistance, making them suitable for applications such as medical equipment, electronics, and precision instruments.

- Coatings and Treatments: In addition to the base materials mentioned above, screw balls may undergo specialized coatings or treatments to enhance their performance. For example, surface treatments like black oxide, zinc plating, or nickel plating can provide improved corrosion resistance. Lubricant coatings or treatments, such as Teflon or molybdenum disulfide (MoS2), can reduce friction and enhance smooth operation.

It is important to note that the selection of materials for screw balls should consider factors such as load requirements, operating conditions, temperature extremes, and compatibility with other components in the system. Manufacturers often provide specific recommendations regarding the materials best suited for their screw ball products based on extensive testing and application experience.

When choosing a screw ball, it is advisable to consult the manufacturer’s documentation, technical specifications, or seek guidance from professionals with expertise in the specific application or industry. They can provide valuable insights and recommendations on selecting the appropriate materials to ensure optimal performance and longevity of the screw ball.

editor by CX 2024-03-06