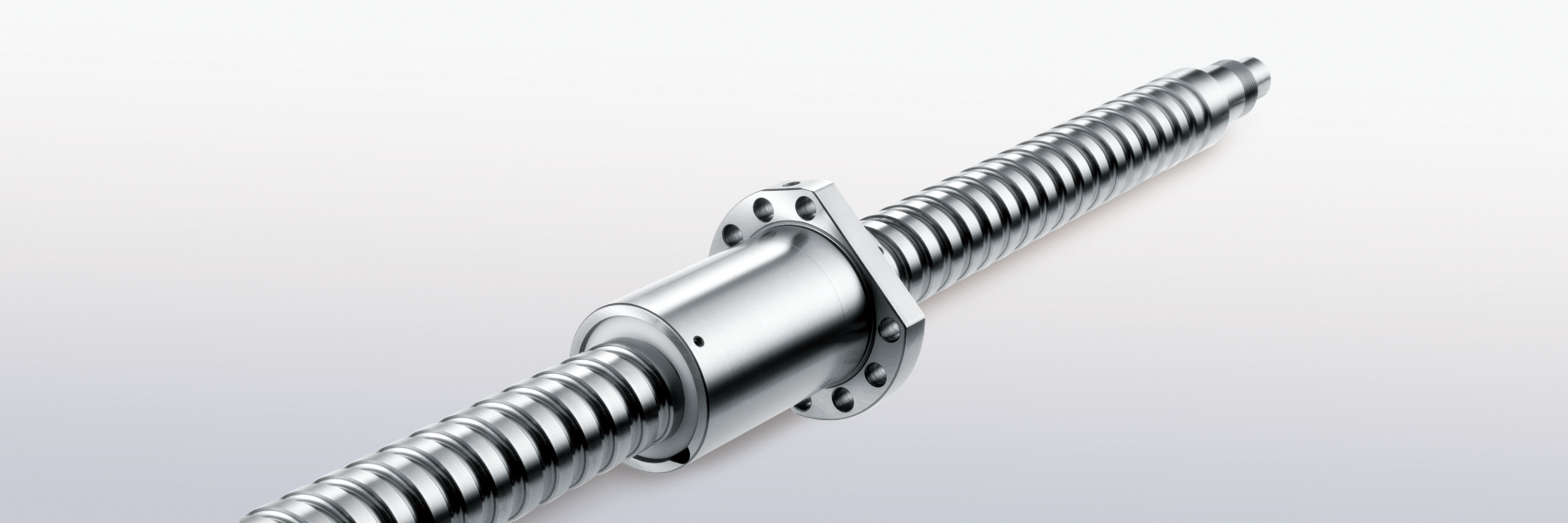

Product Description

|

Chemical composition |

||||||

|

Material |

C |

Si |

Mn |

P |

S |

Cr |

|

52100 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

0-0.571 |

0-0.571 |

1.40-1.65 |

FAQ

1. Can you provide sample free?

We’re pleased to offer you free samples weighing up to 0.5kg. It’s our way of letting you experience the quality of our products firsthand. If there’s a specific product you’d like to try, simply let us know, and we’ll ensure it reaches you promptly.

2. What kind of payment terms you can accept?

We can accept T/T,L/C, Western Union and Paypal.

3. What about your steel ball’s quality?

We pride ourselves on the exceptional quality of our steel balls. Our commitment to delivering top-tier products is evident throughout the entire manufacturing process. Every steel ball undergoes rigorous scrutiny, with a comprehensive 100% inspection conducted before shipment. Rest assured, our dedication to quality assurance ensures that you receive products of the highest standard.

4. What’s your packing method?

A) Inner packing: Dry packing or oil packing are provided according to you needs.

B) Outer packing:

1)volatile rust preventive paper + poly bag + iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

3)customized packing.

5. What’s your delivery time?

Within 3-30 days according to your required size and quantity.

6. Is your steel ball competitive?

Yes, We are steel ball manufacture more than 30+ years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, IATF 16949 |

| Standard Parts: | Yes |

| Samples: |

US$ 20/kg

1 kg(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can screw balls be custom-designed for specific applications?

Yes, screw balls, also known as ball screws, can be custom-designed to meet the specific requirements of various applications. Customization allows for the optimization of the screw ball’s performance, functionality, and compatibility with the intended use. Here are some key aspects of custom design for screw balls:

- Size and Dimensions: Screw balls can be custom-designed to meet specific size and dimensional requirements. This includes variations in diameter, lead, pitch, and overall length. By tailoring the dimensions to the application, the screw ball can be integrated seamlessly into the system, ensuring proper fit and alignment.

- Load Capacity: Custom-designed screw balls can be engineered to handle specific load requirements. This involves selecting appropriate ball sizes, ball nut designs, and materials to ensure optimal load-carrying capacity. By considering factors such as the magnitude and direction of the load, the custom-designed screw ball can provide the necessary strength and durability for the application.

- Speed and Accuracy: Different applications may have unique speed and accuracy requirements. Customization allows for the selection of appropriate ball screw designs, ball recirculation mechanisms, and manufacturing tolerances to achieve the desired speed and accuracy levels. This ensures that the screw ball can deliver the necessary precision and repeatability for the specific application.

- Environmental Considerations: Screw balls can be custom-designed to withstand specific environmental conditions. For example, if the application operates in high-temperature or corrosive environments, the screw ball can be engineered with materials, coatings, or seals that provide enhanced resistance to heat, chemicals, or contaminants. This customization ensures the longevity and reliability of the screw ball in challenging operating conditions.

- Mounting and Integration: Custom-designed screw balls can be tailored to facilitate easy mounting and integration into the overall system. This includes the provision of specific mounting features, end machining, or interface compatibility with other components. By considering the system’s requirements, the custom design ensures seamless integration and efficient installation of the screw ball.

- Special Features and Requirements: Certain applications may have unique features or requirements that can be accommodated through custom design. This can include specialized lubrication systems, integrated sensors, built-in safety mechanisms, or specific certifications. Customization allows for the incorporation of these special features, ensuring that the screw ball meets the application’s specific needs.

Collaborating with manufacturers or suppliers who specialize in custom screw ball design is crucial to ensure that the custom-designed screw ball meets the desired specifications and performance requirements. Through close collaboration and a thorough understanding of the application, the manufacturer can provide valuable insights, engineering expertise, and design recommendations to create a custom screw ball that is tailored to the unique needs of the application.

How do temperature variations affect the performance of screw balls?

Temperature variations can have a significant impact on the performance of screw balls, also known as ball screws. These linear motion systems are designed to operate within specific temperature ranges to maintain their accuracy, dimensional stability, and overall performance. Here’s how temperature variations can affect the performance of screw balls:

- Thermal Expansion: Screw balls are typically composed of different materials, such as steel or ceramics, that have different coefficients of thermal expansion. When the temperature changes, each material expands or contracts at a different rate, leading to dimensional changes in the screw ball components. This thermal expansion can introduce misalignment, increased backlash, or changes in preload, affecting the accuracy and repeatability of the linear motion system.

- Lubrication: Temperature variations can impact the properties and performance of the lubricant used in screw balls. Lubricants have specific viscosity and temperature ranges in which they function optimally. High temperatures can cause lubricants to thin out, reducing their ability to provide sufficient lubrication and increasing friction between the ball bearings and the raceway. On the other hand, low temperatures can cause lubricants to thicken, impeding smooth motion and increasing resistance. Insufficient or improper lubrication due to temperature variations can lead to increased wear, reduced efficiency, and potential premature failure of the screw ball system.

- Material Integrity: Extreme temperature variations can affect the mechanical properties and integrity of the materials used in screw balls. High temperatures can cause thermal degradation, softening, or even melting of certain materials, leading to reduced strength, increased wear, and potential deformation. Conversely, low temperatures can make materials brittle and more susceptible to fracture or failure under load. It is important to consider the temperature limits of the screw ball materials to ensure their structural integrity and long-term performance.

- System Rigidity: Temperature changes can affect the rigidity and stiffness of the screw ball assembly. When subjected to high temperatures, the components may expand, leading to a decrease in overall system rigidity. This reduction in stiffness can result in increased deflection, reduced accuracy, and diminished load-carrying capacity. Conversely, low temperatures can cause contraction and increased system rigidity, potentially affecting the smoothness of motion and overall performance.

- Sealing and Environmental Protection: Temperature variations can impact the effectiveness of seals and environmental protection measures in screw ball assemblies. Seals play a crucial role in preventing contaminants, moisture, and debris from entering the system. Extreme temperature changes can cause seals to degrade, lose flexibility, or become brittle, compromising their sealing properties. This can result in increased risk of contamination, accelerated wear, and reduced performance of the screw ball assembly.

To mitigate the effects of temperature variations on screw ball performance, several measures can be taken. These include:

- Choosing materials with suitable temperature resistance and low coefficients of thermal expansion.

- Using lubricants that are specifically formulated for the expected temperature range.

- Implementing temperature compensation techniques to maintain dimensional accuracy and alignment.

- Applying thermal barriers or insulation to minimize the transfer of heat to the screw ball assembly.

- Ensuring proper sealing and protection from extreme temperature environments.

- Using temperature control systems or environmental enclosures to maintain a stable operating temperature.

By considering the potential effects of temperature variations and implementing appropriate measures, the performance and longevity of screw balls can be optimized, ensuring accurate and reliable linear motion in various applications.

How do you install a screw ball in machinery?

Installing a screw ball or a ball screw in machinery involves several steps to ensure proper alignment, secure fastening, and smooth operation. Here’s a general guide on how to install a screw ball:

- Prepare the Workspace: Start by ensuring a clean and organized workspace. Remove any debris or obstructions that could interfere with the installation process.

- Identify the Components: Familiarize yourself with the different components of the screw ball system, including the screw shaft, ball nut, support bearings, and any associated mounting brackets or housings.

- Inspect the Components: Before installation, carefully inspect all components for any signs of damage or defects. Ensure that the screw ball and associated parts are clean, properly lubricated, and free from any debris or contaminants.

- Align the Screw Ball: Align the screw ball system with the corresponding mounting surfaces or brackets in the machinery. Ensure that the screw shaft is properly aligned with the desired path of motion.

- Secure the Screw Ball: Use appropriate tools and fasteners to secure the screw ball in place. Follow the manufacturer’s guidelines or specifications for torque values and tightening procedures. Be cautious not to overtighten, as it can lead to binding or excessive friction.

- Check for Smooth Operation: After securing the screw ball, manually rotate the screw shaft or activate the machinery to verify smooth operation. Ensure that there is no binding, excessive noise, or abnormal resistance during motion.

- Adjust and Fine-Tune: If necessary, make any adjustments or fine-tuning to optimize the alignment and performance of the screw ball system. This may involve adjusting bearing preload, backlash, or other parameters depending on the specific requirements of the machinery.

- Perform Final Checks: Once the installation and adjustments are complete, perform a final inspection to verify that all components are securely fastened, aligned correctly, and functioning as intended. Double-check for any signs of misalignment, excessive play, or abnormalities.

- Document and Maintain: It is important to document the installation process, including any measurements, adjustments, or specific procedures followed. Regular maintenance, including lubrication and periodic inspections, should be performed as recommended by the manufacturer to ensure the longevity and optimal performance of the screw ball system.

Please note that the specific installation process may vary depending on the type of machinery, the design of the screw ball system, and the manufacturer’s recommendations. It is essential to consult the manufacturer’s documentation, installation guides, or seek professional assistance when installing a screw ball in machinery to ensure proper installation and optimal performance.

editor by CX 2024-03-05